What Is the Difference Between Cob Packaging and Traditional LED Packaging

Introduction

The COB packaging process is not much different from the SMD production process, but the packaging efficiency of COB packaging is much higher in dispensing, separation, spectroscopy and packaging. Compared with traditional SMD, it can save 5% of any costs and materials.

The COB packaging process is not much different from the SMD production process, but the packaging efficiency of COB packaging is much higher in dispensing, separation, spectroscopy and packaging. Compared with traditional SMD, it can save 5% of any costs and materials.

Compared with traditional packaging technology, what are the advantages of COB technology?

High packaging efficiency and cost saving

The COB packaging process is not much different from the SMD production process, but the packaging efficiency of COB packaging is much higher in dispensing, separation, spectroscopy and packaging. Compared with traditional SMD, it can save 5% of any costs and materials.

Advantages of low thermal resistance

The system thermal resistance structure of traditional SMD packaging is: chip - die bonding glue - solder joints - solder paste - copper foil - insulation layer - aluminum material. The system thermal resistance of COB packaging is: chip-die die glue-aluminum material. The system thermal resistance of COB packaging is much lower than that of traditional SMD packaging, so the service life of COB packaged LED lamps is greatly improved.

Light quality advantage

Traditional SMD packaging attaches multiple discrete devices to the PCB in the form of patches to form light source components for LED applications. This approach has problems with spot light, glare and ghosting. The COB package is an integrated package and a surface light source. It has a large viewing angle and is easy to adjust, reducing the loss of light refraction.

The traditional SMD packaging method is to attach multiple different devices to the PCB board to form an LED light source component. Light sources made with this packaging process commonly suffer from electro-optical, ghosting and glare problems. COB light source does not have the above problems. It is a surface light source with a large viewing angle and easy adjustment of the angle, which reduces the loss of light due to refraction.

Application advantages

COB light source is very convenient to apply and can be directly applied to lamps without other processes. The traditional SMD packaged light source needs to be mounted first and then fixed on the PCB board through reflow soldering. It is not as convenient as COB in application.

About DDW Display

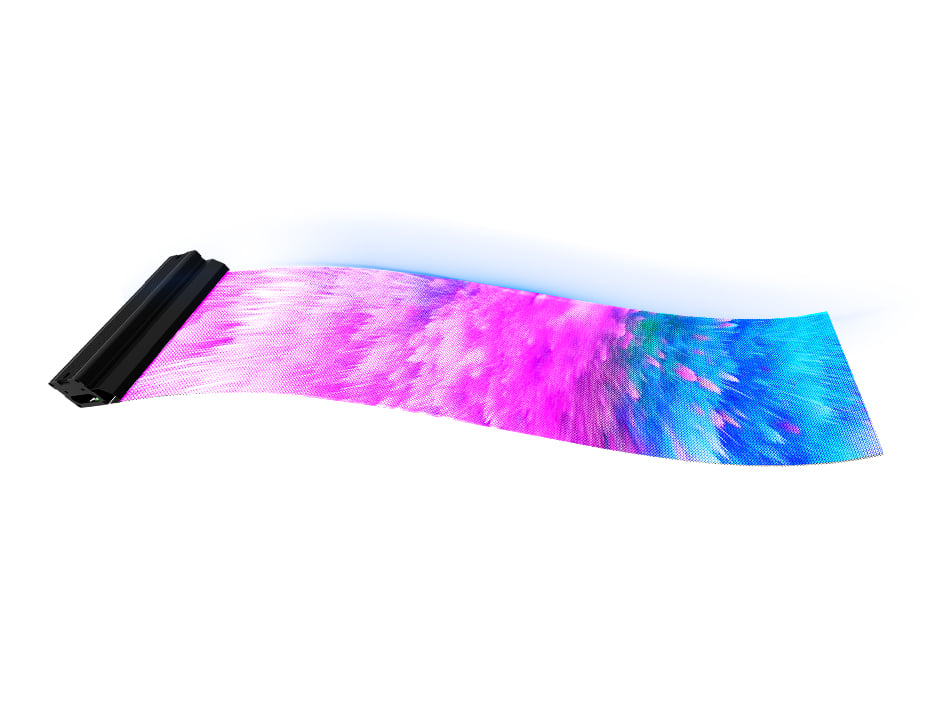

Shenzhen DDW Technology Co, Ltd is a professional manufacturer and developer of LED display screens in Shenzhen, China since 2012.We're a company focus on indoor outdoor rental LED screen, fixed LED screen, HD LED screen, flexible LED screen, transparency LED display, creative led screens and customization services.

If you are in need of LED displays, kindly contact us today.

Language

Language